In our ongoing blog series “Customer portals: The next big thing in B2B Manufacturing,” we’ve dissected the current challenges many manufacturers face as well as the driving forces behind the need for digitalization. This third installment will explore the concept of the composable manufacturer. What does this approach entail for manufacturers, and what are the benefits of “componentizing” challenges within your IT landscape?

When manufacturers aim to provide services through customer portals, the initial impulse often leads towards off-the-shelf software solutions. However, these solutions are typically designed for a broad audience and may not differentiate your offerings from competitors. Let’s explore why adopting a best-of-breed composable solution allows you to stand out by offering a customer portal tailored to your business processes.

Tailored solutions vs. One-size-fits-all

Many industrial manufacturers opt for commercial off-the-shelf platforms hoping for a one-size-fits-all solution. Yet, they often discover that these solutions are more limiting than universally applicable. Monolithic solutions come with broad, inflexible functionalities that can mismatch features and user experience. Alternatively, a composable architecture offers a “fit for purpose” approach, focusing on the customer and their specific needs. By integrating components that directly address operational challenges and customer requirements, composable solutions result in efficient, user-friendly customer portals that can adapt to changing market demands and preferences.

37% consider rising customer expectations a threat to their organizational success.

Consider the scenario of aftermarket spare -part ordering – a common task for many manufacturers. Often, they invest in large commerce platforms to digitalize this process. However, these platforms typically come loaded with an array of features, many of which are irrelevant for this specific customer journey. More importantly, they often lack robust functionalities for visualizing assets, which are crucial for identifying the correct spare parts. A fit-for-purpose solution, in contrast, would precisely cater to this need by integrating service/support features with efficient asset management and a streamlined ordering process. A user experience tailored to distinct user roles, such as a field service engineer or a procurement officer, is a pivotal offering. This “fit-for-purpose" approach, enabled by a composable architecture, ensures that the solution is not only more efficient but also more aligned with the actual needs of the users, instead of forcing the users to align to the one-size-fits-all platform.

In service, we need data and it is scattered, so why not embrace digital transformation to support the transition?

Challenges of integration with existing systems

For industrial manufacturers, integrating new technologies with existing systems is a significant challenge. The IT landscape is often scattered throughout the organization, with multiple ERP systems integrated with highly customized legacy commerce solutions. This results in tightly coupled and inflexible solutions that don't scale. Composable approaches tackle this challenge in three unique ways:

- Modularity: Composable architectures are inherently modular, allowing seamless integration with existing legacy systems without requiring extensive overhauls.

- API First: Designing and developing with an API First approach ensures that new components can easily connect to existing ecosystems, minimizing downtime and integration costs.

- Cloud-Native: Developing components as cloud-native applications enhances integration capabilities, leveraging scalability and flexibility for easier management of interconnected systems.

The data tells us that too many companies are stuck keeping the upgrade wheel turning. If you add the cost of time and business stand-still, the absolute cost is much higher.

- Casper Rasmussen, MACH Alliance President, quoted in the MACH Global Research 2023 report

Accelerating feature delivery

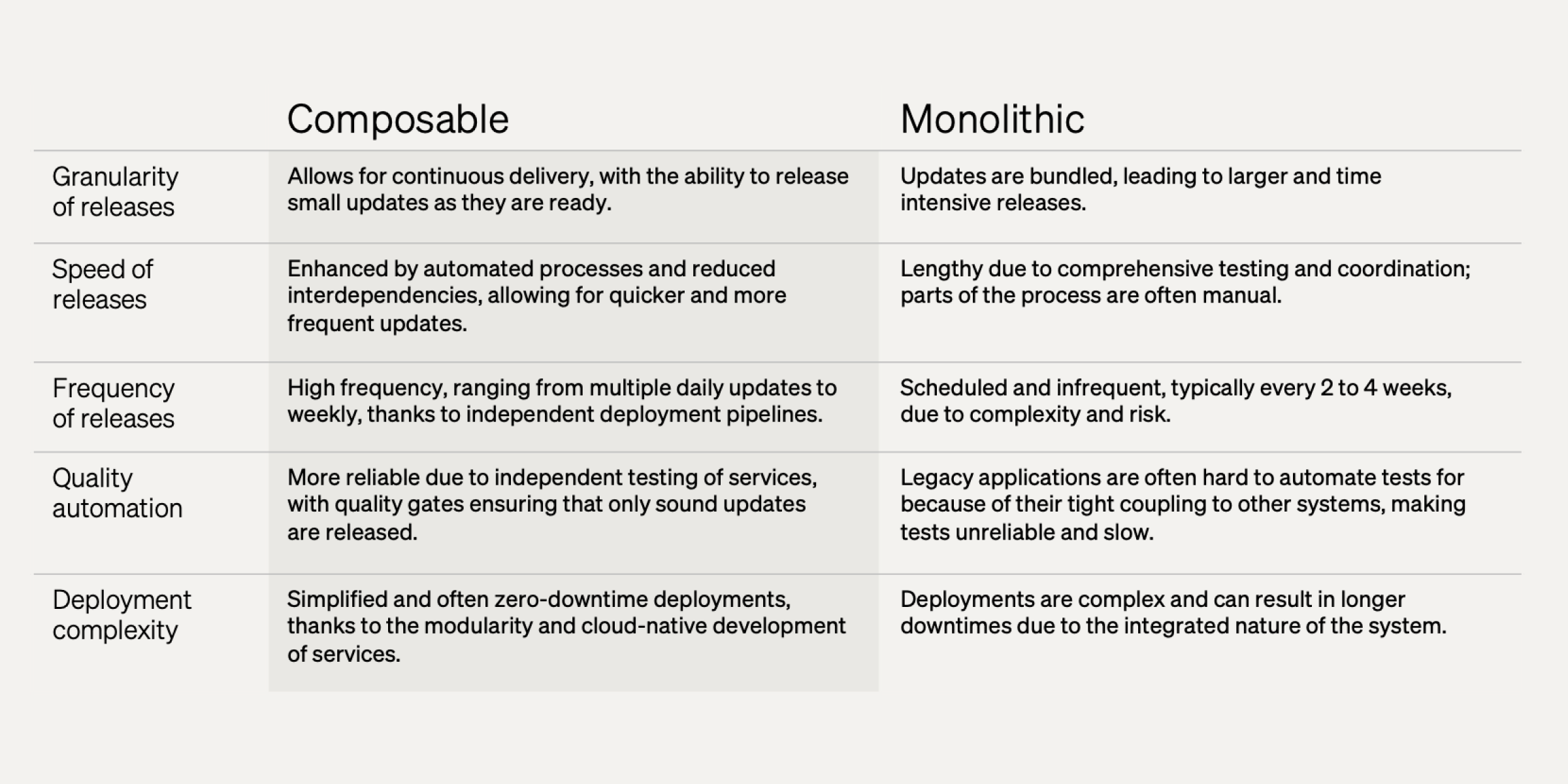

Traditional monolithic systems often hinder manufacturers from delivering timely updates and new features due to prolonged development lifecycles. Composable architectures enable agile, independent component development, speeding up the release process and ensuring rapid adaptation to market demands.

The table below illustrates a clear comparison of how composable architecture transforms the development process compared to monolithic systems.

Gradual data quality improvements in composable systems

The decision that I regret in retrospect is not starting with data quality first, which we missed out on in the beginning.

Many manufacturers struggle with data quality. Composable architectures excel in environments where data quality is variable. By adopting a modular approach, companies can channel high-quality data into certain components, ensuring peak system efficiency and effectiveness. As data quality improves over time, these systems can transition to automated data feeds, continuously improving capabilities without a complete transformation.

Overcoming entry barriers for going composable

There's a common misconception that composable architecture is only suitable for digitally mature companies. However, manufacturers at all digital maturity levels can benefit from a composable approach:

- Emerging/Reactive: Focus on a smaller project or proof of concept together with a strong technology partner.

- Manufacturers at this stage lack a clear digital vision and address digital needs on a case-by-case basis, often lacking in-house expertise for customization.

- Gain experience with managing a single-vendor relationship for a smaller project and build out over time.

- Optimizing/Proactive: Gradually transition to a composable architecture while optimizing digital initiatives across departments.

- Manufacturers at this stage have a clear digital strategy and optimize processes across departments, although they may still operate in silos.

- They adopt a hybrid approach, using enterprise suites for core functions and incorporating composable elements for flexible functionalities.

- Innovating/Leading: Embrace composable architectures for flexibility and innovation, leveraging in-house expertise for effective management of diverse components.

- Manufacturers at this level are industry pioneers and leaders.

- They adopt a fit-for-purpose approach, selecting suitable technologies for each function and integrating them seamlessly.

As we reach the end of our exploration into the composable manufacturing landscape, it's clear that flexibility, scalability and innovation are more than just buzzwords—they're essential components of a thriving industrial future. A composable approach proves invaluable for enhancing customer experiences with customized solutions. It allows for seamless integration of cutting-edge technologies and enables agile responses to market shifts. This strategy fosters nimble decision-making and operational adaptability previously reserved for industry pioneers.

By embracing composable solutions, manufacturers prepare to meet today's demands and pave the way for a resilient tomorrow. Keep in mind that the transition to a composable system doesn’t happen with a simple flip of a switch. It’s a journey of continuous improvement and adaptation, ultimately leading to a robust, future-proof manufacturing system.

In our final installment of this blog series, we’ll explore practical steps to implement a composable infrastructure using Valtech’s B2B customer portal accelerator GEAR, based on commercetools. Stay tuned for actionable insights to transform your knowledge into tangible results.

Interested? Contact us today to talk to one of our experts about the possibilities for customer portals in industrial manufacturing.