This is the third article in our Factory Tour series. If you haven't done so yet, we recommend you to also read the first and second article.

Introduction

The Factory model was developed by members of Valtech’s Composable Commerce Center of Excellence, in response to working with complex organizations who wanted to undertake a significant commerce transformation. The Factory focuses on ways of working, while reducing the total cost of ownership, and ensuring that the uniqueness of each brand across the organization is preserved.

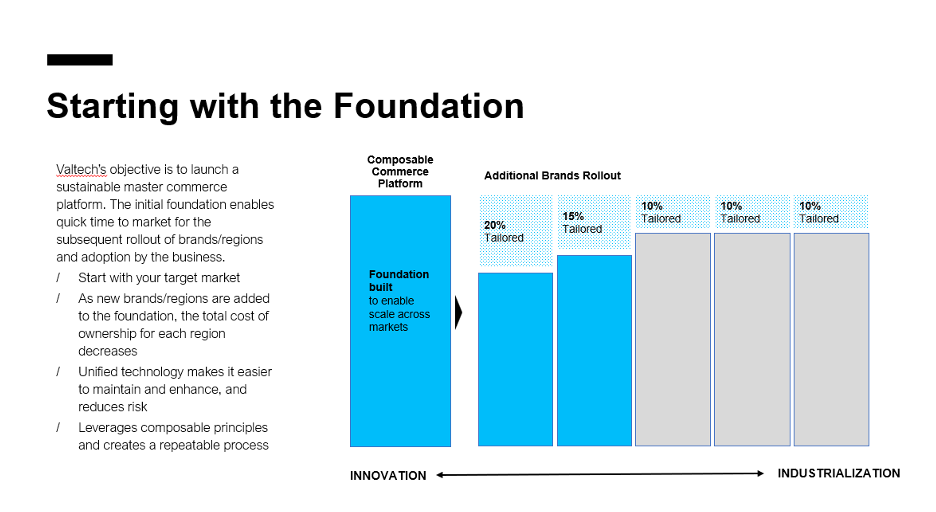

The Factory model was designed to be vertical agnostic. The key inputs, in determining the ideal approach for your organization to transition from a monolith to a completely decoupled and composable architecture, include the clear understanding of the ambition of the project and identifying the global goals. The alignment on key artifacts such as the governance program, ways of working and the Factory principles, should result in identifying the executive sponsors and core team needed for the transformation. After establishing the scope, the governance program, and the team structure – the organization can then determine the foundational composition of the Factory. The foundation is the key to the success of the Factory model, as it will support all the multiple brands and regions.

This article will give an insight on the principles governing the Composable Commerce Factory model, and whether this approach makes sense for your organization. Due to the unique context of each organization and their brands, this article is meant to be a baseline for understanding the Factory - a baseline that would be adapted to your current realities, and future endeavors. Valtech’s team of composable experts can assist your organization in establishing a path forward to building a successful and modern architecture for your commerce ecosystem.

The factory concept

The Composable Commerce Factory was developed with a series of guiding principles at the forefront; unification of the technology stack across the broader organization; leveraging best-in-class or best-of-needs Software as a Service solutions - which follows MACH principles; and enabling flexibility for each brand/region’s uniqueness. Other important considerations are faster time to market and lower total cost of ownership (TCO). If we were to draw a comparison, think in terms of an actual physical factory – there are machines and common tools used to create products; on top of that, there is flexibility to create specific, custom products comprised of both unique and common components. In the digital Composable Commerce Factory, the common components are the commerce foundation solutions that all brands will share, i.e. cart, payment gateways, ERP, OMS, etc.

Streamlining processes in terms of standardization, while allowing for flexibility, creates the “bring your own” opportunity for each brand. With the goals of speed and lowered cost being part of the Factory’s north star – “bring your own” means each brand can select which new or current solutions are core to that brand’s digital experience. Some differentiating elements defined in the Factory, to account for a particular brand’s uniqueness or region include storefront, marketplace integration, chat / CSR, user generated content (UGC), ratings & reviews, etc. The goal is to not reinvent the wheel but to leverage the tools that currently exist and power each different brand.

Another goal is to increase speed to market – by building a foundation and reusing that foundation as new brands and/or regions are being onboarded, an organization is able to stand up new brands or regions more quickly. This improved time to market equates to achieving a positive ROI in less time, lower TCO and enables business users to explore more innovative opportunities. The Factory not only speeds up technology implementations it is also about organizational adaptation: streamlining internal processes and ways of working with operational playbooks and unified user guides decreasing the time needed to train users on new tools.

While the Factory can be a game changer, future ready and scale model for many organizations, there are a specific set of requirements that must be kept in mind before undertaking the building of the Factory foundation. This solution solves for multi branding and/or multi regions so it is important to come up with an approach relative to how the organization plans to approach separation of TCO across the brands and regions – since multi-brands are leveraging a single base this approach differs from the traditional budgeting scenarios. Cost attribution is key to empowering each brand – ensuring the proper organizational structure needed to support the future Factory, people, and processes.

Factory activation approach – The nine principles

The Factory model is built on nine core principles and each of them should be considered when starting the digital transformation. These principles have both far reaching technical and organizational impacts to success and adoption.

The principles are:

- MACH & MACH Friendly

- Less is more – Adopt existing vendors over new ones

- Works towards a data-centric eco-system

- Enable brand’s uniqueness

- Compliance with existing APIs, standards, monitoring and security

- Solutions that can operate in open environments with lots of contributors

- Capabilities first / configuration over customization

- Event-driven, async and decoupled

- Portability via isolation of brand, region, and operations

MACH & MACH friendly

Typically, an organization initiates a digital transformation to overcome the shortcomings of their current tech stack and often, this implies the transition, away from a monolith-type solution or an in-house build legacy solution. Establishing a foundation, which is embraces microservices, APIs-first, Cloud native SaaS solution and headless technologies – in short, MACH – is what we refer to as modern enterprise architecture.

Key elements to consider are:

- Modularity in functionality

- Ability to adapt quickly to changes

- Scale independently

- Enable innovation and easily evolve over time

Less is more

Prior to the implementation of the Factory, it is critical to “catalog” each and every vendor in the ecosystem and across all brands and subsequently, to assess whether they are a fit, holistically in the future architecture. The goal is to leverage existing relationships, existing software solutions, and existing internal knowledge (functional and technical). During this process, the technological landscape will result in the actual architectural state, with the goal of identifying the overlaps. The goal of this exercise is to identify the best fit solution for the targeted needs, and limit vendor sprawl in the new ecosystem.

The goal is as much to leverage existing solutions as it is to create a vetted group of vendors that support the future ecosystem, so that brands have a catalog of solutions to choose from to execute technical innovation quickly. Not all existing vendors will be a good fit for the future ecosystem and each one should be considered on a case-by-case basis, vetted against future state technical and business requirements.

Data centric ecosystem

Working towards a data-centric ecosystem is also fundamental to the Factory; it takes siloed and independent data points and brings them together into a central repository where a new set of enablers can be created. Often referred to Big Data, this valuable set of information can be leveraged to increase brand awareness, drive personalized experiences and ultimately, increase conversion.

“The term Big Data itself may not be as ubiquitous as it was a few years ago, and that’s purely because many of the concepts it embodies have been thoroughly embedded into the world around us. But just because we've heard about it for a while, though, doesn't mean it’s old news. The fact is that even today, most organizations struggle to get value from a lot of the data they have access to. As a business practice, it’s still very much in its infancy.” Forbes

The goals are to centralize the data, structure it for maximized usage and organize it in a way that empowers both the business users and AI experiences. This type of data centralization is required to power future experiences. Customers are no longer afraid of a customized digital experience; quite the opposite in that they now expect it as the norm. Starting with personalized experiences gives brands the ability to ideate on the future state ecosystem that will power the 360-degree immersive experience, where a transaction becomes a by-product of the relationship and brand loyalty is earned, nurtured, and maintained by these unique experiences. This future state drives value to the business as well as the customer.

Brand giving back to the factory

Enable brand’s uniqueness

Creating these unique, immersive cross-touchpoint journeys should be specific to each brand within the portfolio. While sharing a common set of capabilities amongst the portfolio of brands, referred to as the foundation, brands should also have the flexibility to introduce what sets them apart and empower their differentiators, reinforcing their competitive edge, not only within the brands of the portfolio but also from their competitors.

“Composable UX seeks to provide the UX for the right customer persona, for the right task, and at the right stage of the customer’s relationship with the organization.” (Gartner)

Enabling marketers to build unparalleled user experiences in the internet of things (IoT) will set brands apart in the future, especially those with luxury and technically savvy consumers.

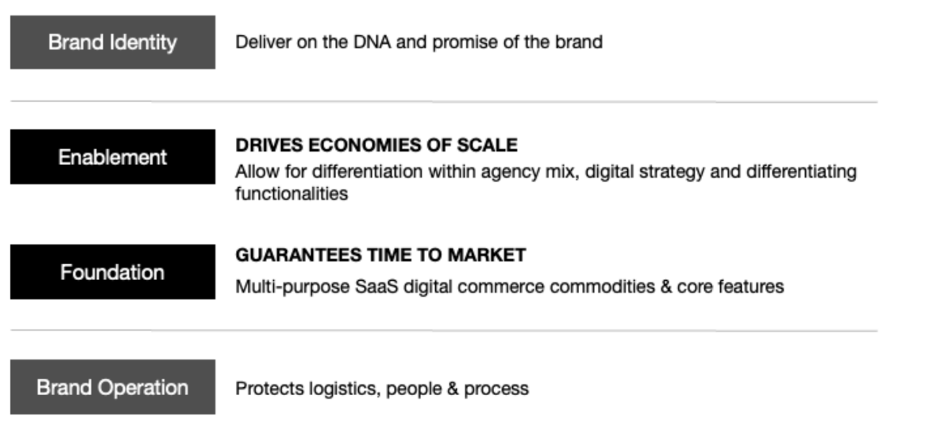

Four layers of capabilities

API compliance

While not as flashy as Internet of Things, immersive brand experiences, security and compliance are equally important to the full brand experience. As privacy laws change, and consumers become more aware of what they are sharing and how to control their online data; a negative privacy or security experience could not only lead to a loss of customers but also project a negative brand image/perception.

Creating standardization for APIs, monitoring and security processes requires a shared definition in ways of working as a team. Ways of working should include, but are not limited to, documentation around project management, technical details and functional specifications. These ways of working - combined with the development standards in shared processes like tagging, automation, and security - set the stage for the Factory's foundation which ensures API compliance in both the initial development as well as for the day to day run the business activities.

Capability over customization

The Factory leverages MACH principles for a variety of reasons. It values capabilities and configuration first and foremost over customization. Monolith solutions are opiniated, and often, one needs to work around it to try and achieve its business objectives. More often than not, organizations are bound to the limitations of the solutions, and therefore, the software limits innovation. For this reason, over time, many organizations have massively over customized those solutions. This creates an enormous burden to be able to scale and to migrate away from these solutions.

MACH, being decoupled by its nature, discourages hyper customization of solutions in favor of flexibility and independent services. When evaluating what solutions to include in the Factory, each brand must evaluate what tools are currently being used; validate they are being used the way they were intended to and in the most optimal way and if they are needed for the future ecosystem as opposed to forcing functionalities into solutions where they do not belong.

Event-driven

Another advantage to a decoupled architecture is enabling an event-driven ecosystem with the guiding principle of ensuring that the right level of abstraction is at the right place, at the right time. Promoting this type of approach requires an in-depth review of the level of abstraction for each event.

Multi-contributors in open environments

One of the main goals of the Factory is to unify and standardize the technology stack across a portfolio. With such a setup, it is important to define the ways of working around environment accesses. Internal teams across brands might have specific needs related to the different set of tools. Additionally, it will not be uncommon for different external solution integrators to collaborate on the various work streams. With that in mind, when building the foundation, consider how you will enable different users to access the solutions – both for internal teams at the project, program and regional level and multiple types of external agencies that will be needed to support the release of different experiences

In order to gain alignment across teams it is key to set up standardized measurements and practices. Having focused KPIs around delivery and documentation standards along with a detailed onboarding process for new team members creates an aligned mindset within the teams. Ensuring teams have and are using collaboration tools is also key to cross functional communication. The teams culture and ways of working should be monitored, adjusted and supported by the leadership members so that the transformation and foundation creates a predictable, repeatable result – essentially what defines and powers The Factory.

Portability

Another consideration is to ensure that a brand can be portable – meaning they can be enabled to be autonomous by isolating brands, regions, and operations. This portability will ensure the onboarding of new brands and regions, but it will also facilitate the offboarding in the event of a brand’s exit of the portfolio.

“Valtech was an obvious choice, for many reasons. They have this huge blend of digital marketing knowledge, technology forte, agile strength, and this change management that they bring to the whole project because it's a very complex project. It's 15 brands and 60 countries. They also bring global-local flavour to the project and again, when you're a big company like us, you need to be able to both support the brands centrally without neglecting the local needs. Because consumers in Thailand are very different from consumers in the U.S., obviously, so this knowledge of Valtech and the fact that they are this big global footprint helped us a lot on that.”

Lubomira Rochet, former Chief Digital Officer at L’Oréal.

Factory challenges & considerations

The Factory has many positive implications for an organization’s digital transformation but there are also multiple considerations that must be addressed to ensure the organization-wide adoption. It is of utmost importance for all impacted business teams to be aligned with the technical solution. When standing up a Factory, this alignment can make or break the success of the digital transformation. Prior to starting the technical build, teams should be aligned on the vision and goals across all brands. This can also be challenging considering that often times, the brands are run independently. The Factory approach requires all brands to agree on the overall vision – making it all the more complex having various brands and teams.

Another consideration to take into account is the organization’s team structure - especially if moving from a traditional monolith to a SaaS-based Factory. The SaaS Factory requires new skill sets. During the transformation, the organization should rethink roles and responsibilities, mapping them back to Factory, for both tech teams and the business. Create a plan to grow the internal teams as well as the future leadership model, talent and acquisition plan, and personal development models.

How the teams work together will also impact the organization’s operations including governance, ways of working, on-boarding processes, and multi-vendor collaboration guidelines. It is typical to have multiple system integration partners and in order to be successful, operations should be well documented and communicated efficiently. A set of documentation will include, and not limited to release management, team composition, management tools, and maintenance & support.

Transformations rarely starts with a blank canvas. There are legacy systems that are likely to be diverse across brands, or the same systems with different versions – this disconnected eco-system can increase implementation challenges (commerce, CMS, etc.) depending on the number and types of systems currently being leveraged. While doing the exercise of thinking about the Factory, take the opportunity to evaluate the existing solutions for current and future needs. The selection of tools is important for the business users. It will be critical to ensure that they are trained to use the tools to maximize efficiency for both productivity and cost efficiencies.

There are multiple ways to transition from a monolith to a SaaS-based architecture. At one extremity, we have the “big bang” approach, whereas the other end, we have the gradual transition. The “big bang” approach consists of migrating a complete set of applications, and its associated set of data at one point in time. This approach has a high level of risk and should be considered in specific cases. One of those cases could be when internal teams are very siloed and where communication between them are non-existent. The “big bang” approach would force the teams to closely collaborate and bridge any existing gaps.

The gradual transition, also known as the “Strangler” approach, enforces the maintenance and the evolution of two solutions for a period of time – the monolith and the SaaS in the scope of this article. With time, functionalities will be migrated from one solution to the other, with the end goal of replacing the initial solution. Besides the apparent lower risks in comparison to the “big bang” approach, it allows for an organization to evaluate the changes that are put in place. From the learnings, the organization can then adapt, evolve and bridge the gaps in any shortcomings, before the introduction of other functionalities, or before scaling to other regions.

Conclusion

The Factory model is without a doubt a massive transformation. However, this strategic transformation, if done correctly, will enable multi-brand/multi-region organizations to operationalize its global growth. It is of utmost importance that organizations must consider not only the technical implications related to the transformation, but also the impact on the people and the processes in the long term. Reaching a base Factory is a process that, if done correctly, takes time. During this process it is important to communicate expectations to all stakeholders within the organization. It has been shown that having at least two cross functional executive sponsors help in effectively communicating the state of the transformation between the different leadership teams and the Boards.

Organizations must also balance the goals it is trying to achieve with a commerce transformation and the day-to-day operations. When implementing a MACH architecture, there is no one size fits all solution. This makes the approach desirable to the endless opportunities for future ecosystems. On the flip side, it can also create bloat, overlap and business user confusion. Let’s not forget that modern digital transformations are a sliding scale, and therefore, unique to each organization.

Other articles in this Factory Tour series:

Part 1: An Industrialization of Composable Commerce

Part 2: Why, When and How to Leverage Composable Commerce for your Business

About the authors

Karen Light, Director of Digital Platform Strategy, Valtech North America

Karen has 20+ years of experience in DTC and B2B retail leadership positions in a variety of roles including merchandising, product development, ecommerce and most recently spearheading the composable digital transformation strategy at SmileDirectClub. She has a strong focus on the digital customer experience and innovation, known for pushing the boundaries of “what if” that can be translated into a strategic plan based on data and value to the business.

Jerome Chan, Director of Ecommerce, Valtech North America

Jerome has 15+ years of experience in the commerce space with an in-depth understanding of the technical needs and challenges to successfully bring a project live. His focus was primarily driven by monolith applications when a few years ago, the attention shifted to a composable mindset. He thrives in collaborating with multiple stakeholders, leveraging his technical experience, and providing strategic approaches for any endeavors, big and small.