Technological trends reshaping manufacturing

Technological trends like Industry 4.0 are driving modern manufacturers towards digital and sustainable transformations. Technologies such as IoT, AI and robotics are reshaping manufacturing processes, enabling initiatives like digital twins for assets and facilities. The key challenge lies in creating an environment where customers can seamlessly access all these digital services – or in other words, a customer portal.

Main challenges in industrial manufacturing

Despite these advances and trends, B2B manufacturers face common technological and organizational challenges.

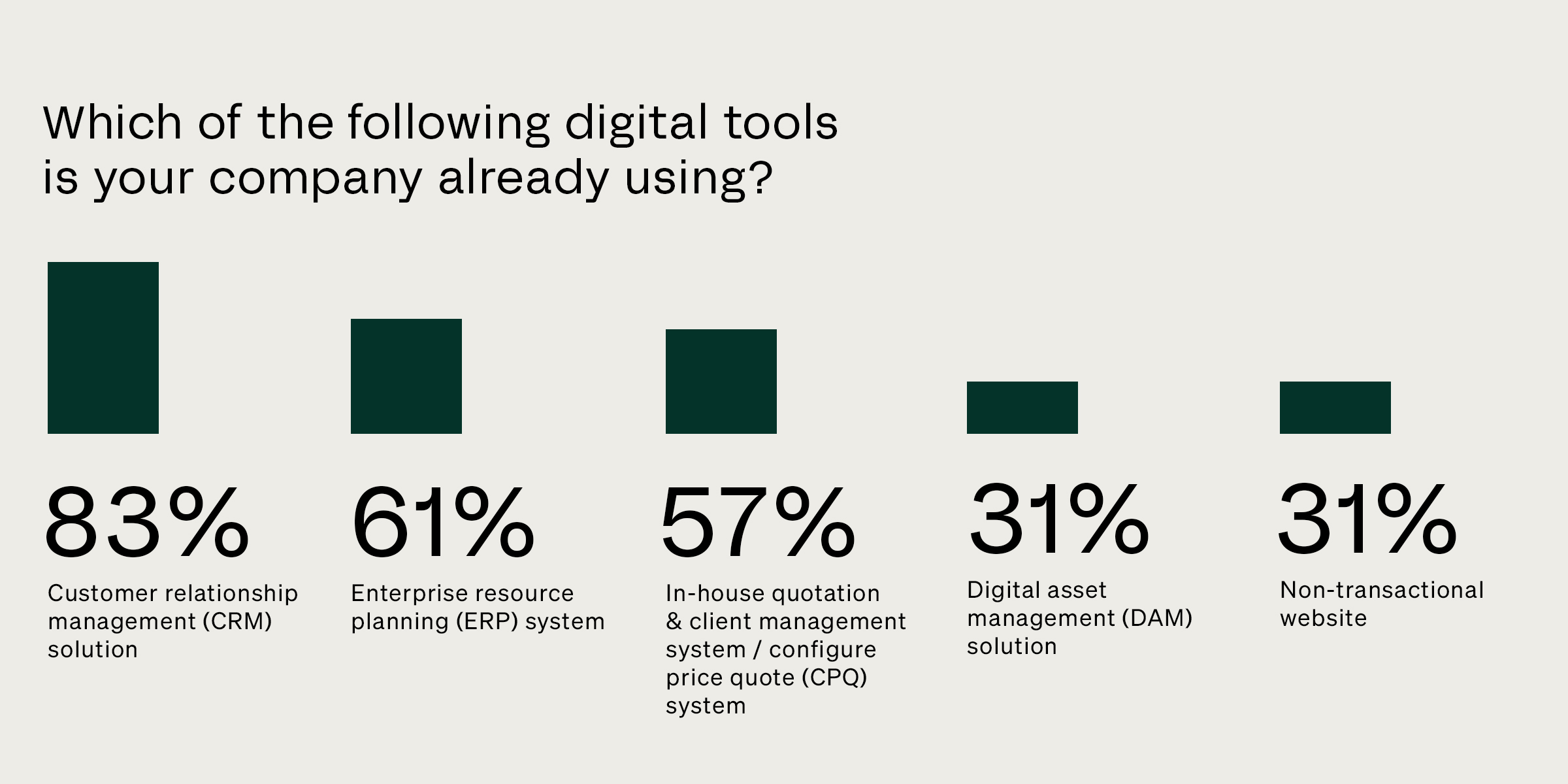

Fragmented legacy landscape

Manufacturers’ legacy systems hinder integration and scalability, as they were not designed with these in mind. Some platforms may provide the data through easy-to-use APIs, while others need custom-built integrations or a manual export. This lack of compatibility is a barrier when building digital services that require data flow between various platforms.

Manufacturers are eager to create the same responsiveness and customer centricity online that their sales representatives traditionally offer. Their struggle, however, is in inflexible monolithic software setups that impede easy and quick deployment of adjustments or new feature development. This creates long lead times for adapting to customer needs and hinders progress towards a customer-centric approach.

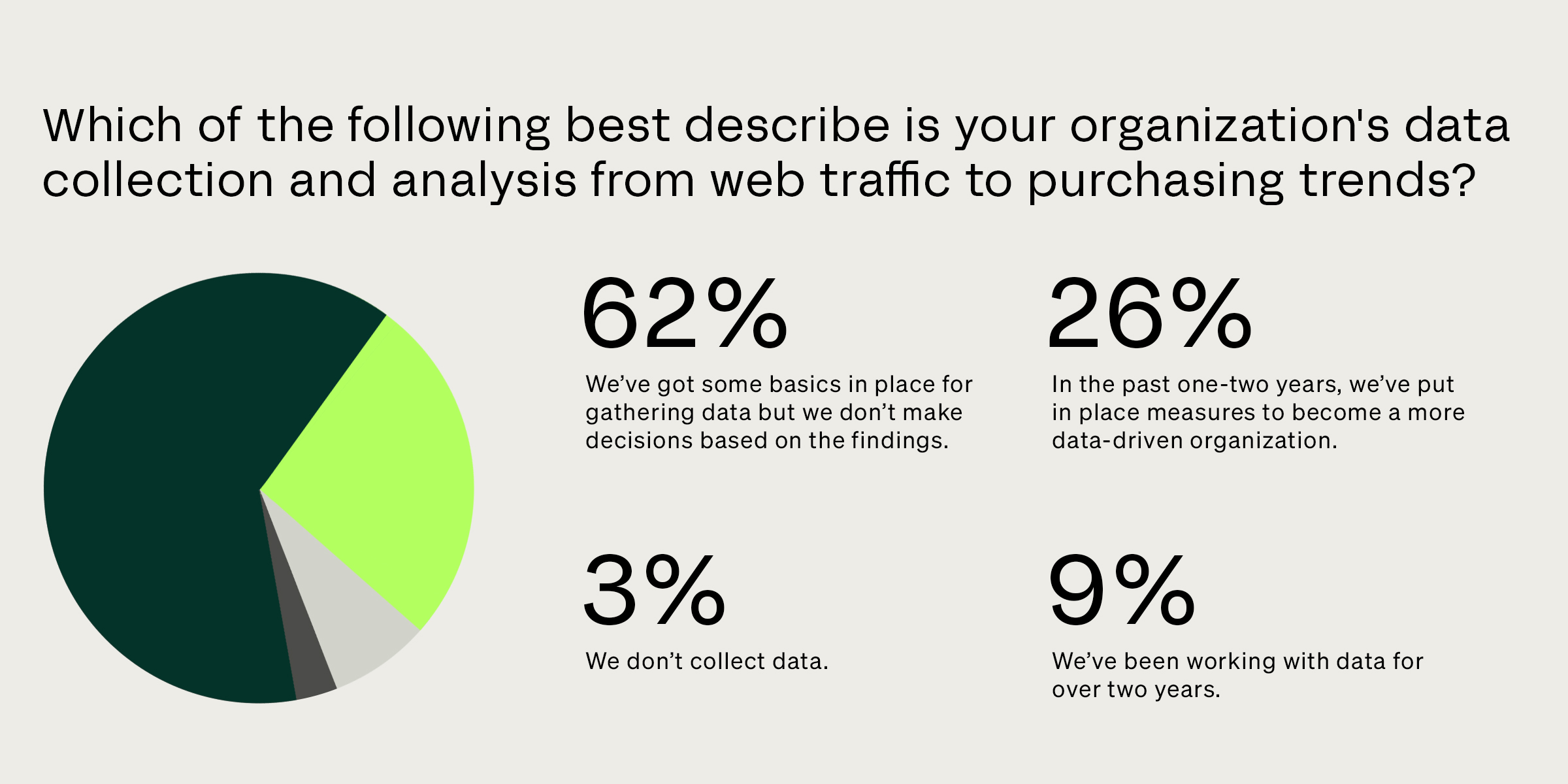

Low data quality

Data quality issues continue to persist due to manual data management.

Internal data systems often have several obstacles to using that data effectively. Common implicit knowledge lives in people’s minds and tends to be recorded less often, which leads to missing, incomplete or mislabeled data. This prevents manufacturers from sharing it with customers without a manual process first. It is common to see manual data management processes for critical business data in tools like Excel or Access. This is highly inefficient and creates a high risk of error.

Resistance to change

A significant barrier to digital transformation is organizational inertia and long lead times for adapting to change.

Teams and individuals may be resistant to change for several reasons. They might not believe in or understand the benefits of digital initiatives, be afraid of losing their jobs, resist the learning curve, or perceive their work as their own domain which is not to be interfered with by new initiatives. Any of these factors can slow down or even sabotage the implementation of new technologies and processes.

Without change management supporting the strategy it is very hard to get full acceptance of the organization for the digital transformation.

– The Voice of Digital Leaders in Manufacturing 2024, Valtech

Other challenges

The struggle to retain and acquire talent has become a prominent issue, as the industry requires skilled professionals to drive innovation and maintain competitiveness. Additionally, the ever-evolving cybersecurity environment demands continuous efforts to protect sensitive data and operations. Manufacturers must also adapt to new regulations concerning privacy and data, especially in the EU, all while managing the complexities of global markets. Furthermore, the lack of leadership support for adopting digital initiatives in some organizations still hinders their ability to respond to these challenges effectively.

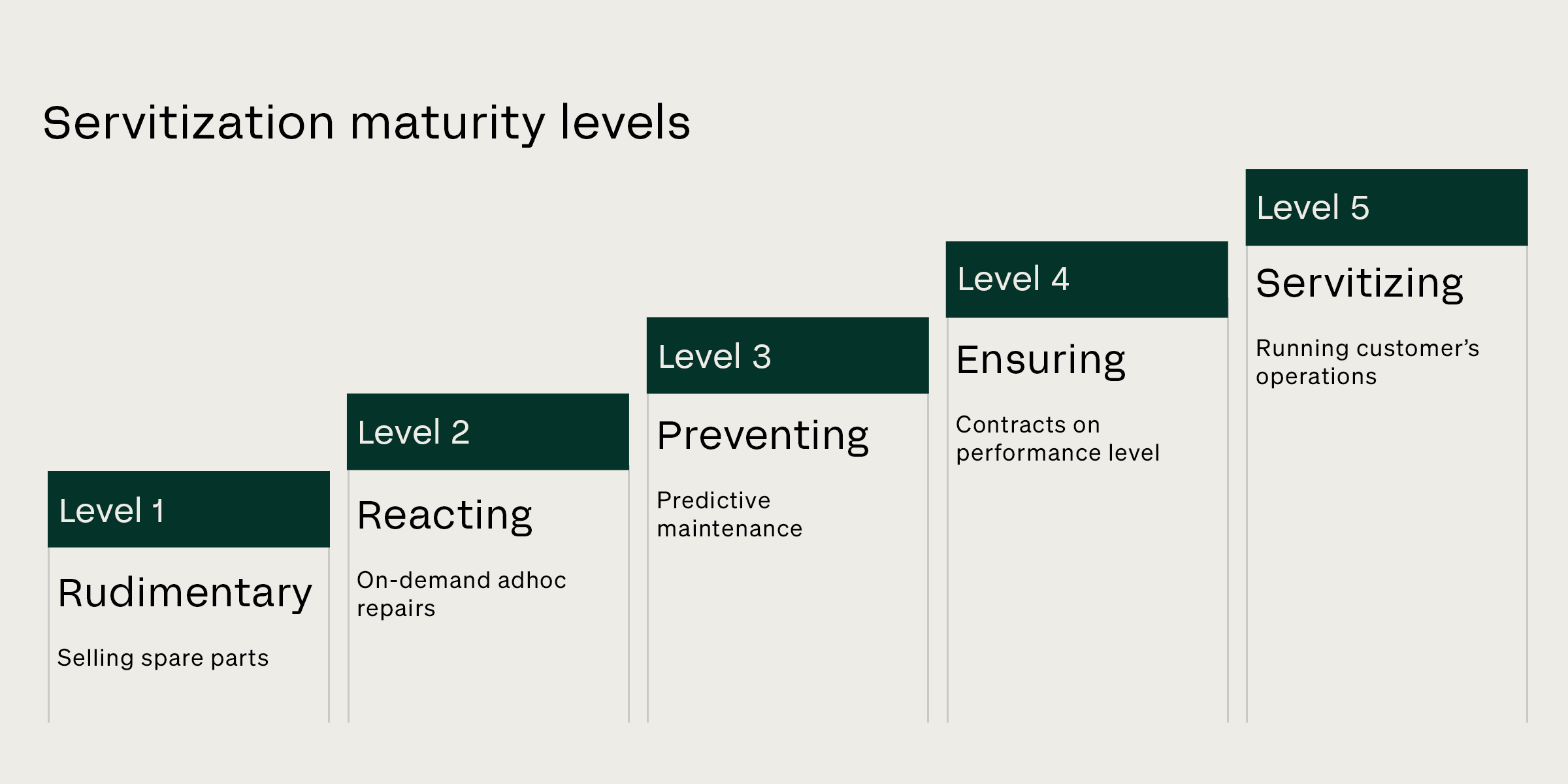

Strategic imperatives for manufacturers

To make the servitization ambition a reality, B2B manufacturers need a solid digital foundation of well-integrated software applications and deep data integration. This makes digitalization stand out as a strategic priority. The current organizational context makes it challenging for manufacturers to adapt to changing technological developments and customer demands. At the same time, some digital leaders are leaping forward by moving along with Industry 4.0 from traditional production models to more advanced, interconnected and intelligent systems.

Stay tuned for the next installment in this blog series! We’ll explore how digitalization benefits manufacturers and how customer portals address their challenges and create value across multiple fronts.